The supply and installation of large-scale chilled water piping systems is a complex and critical undertaking, typically required in industrial, commercial, and institutional settings where substantial cooling capacity is necessary. These systems are designed to handle the cooling needs of vast spaces, such as data centers, manufacturing plants, and large office complexes.

The supply phase involves procuring the appropriate materials, such as high-quality pipes, valves, pumps, and insulation, which are essential for efficient and reliable chilled water distribution. Additionally, careful planning and design are essential to ensure that the system meets the specific cooling demands of the facility and is cost-effective over its lifespan.

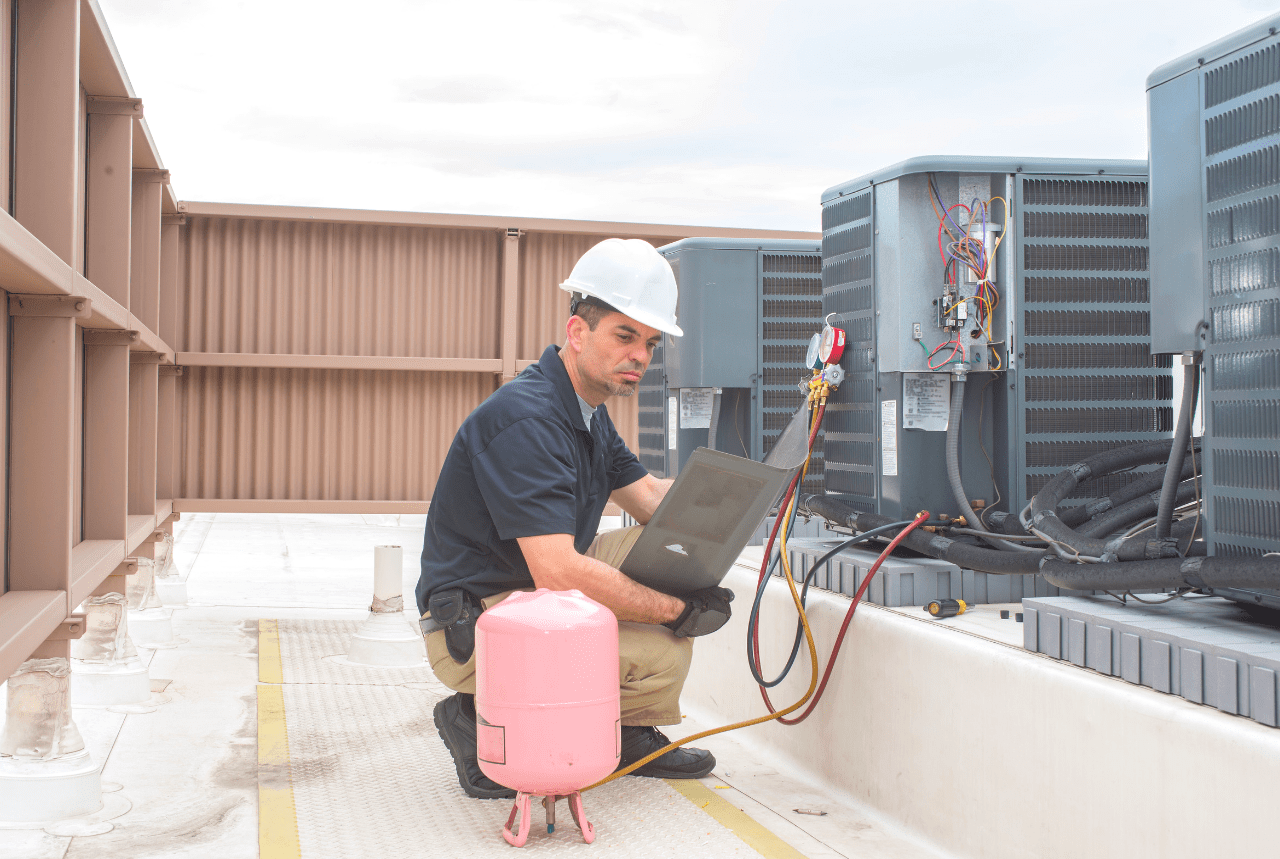

Installation, on the other hand, is a highly specialized process, often necessitating skilled technicians with expertise in welding, fitting, and system integration. Precision is paramount to guarantee leak-free connections, optimal flow rates, and temperature control. Safety measures are also a priority to protect both personnel and the environment.

These extensive chilled water systems offer a range of benefits, including energy efficiency, reduced maintenance costs, and the capacity to provide consistent cooling for extensive spaces. They often incorporate advanced control systems and monitoring technology to maximize performance while minimizing waste.

In conclusion, the supply and installation of large chilled water piping systems are significant undertakings that play a pivotal role in maintaining temperature-sensitive environments. Their successful implementation is crucial for ensuring efficient and reliable cooling in facilities where uninterrupted operations are imperative.